Prototype Titanium Band

TIBAND

Sold Out

Free Shipping U.S. $100+

12-Month Warranty

100% Secure Checkout

Hand-Inspected Quality Control

Features

What are these prototypes?

The look I was going after personally was links that would not detract from the case of the COURG. i.e. I wasn’t interested in something overly chunky or ornate or busy. In two words: functional and sleek.

Manufacturing in titanium is super expensive. You can imagine making a titanium strap would be quite an undertaking.

So, I resolved to find the closest design to what I envisioned just so I could at least see if it was in the right territory. The closest one I could find in titanium is from a German company and it turned out to be a flexible / expandable band.

Process, process, process.

I don’t know about you, but I really can’t stand when there’s a gap between a band and the watch case. Is there a term for that ugliness? One of you on IG spotted a shot I took of a way early field test without end links and called me out! Hahaa.

Anyway, after I got my hands on one titanium flex band and felt it was good enough for a placeholder, I knew I’d need endlinks. So, I hand drew an end link design.

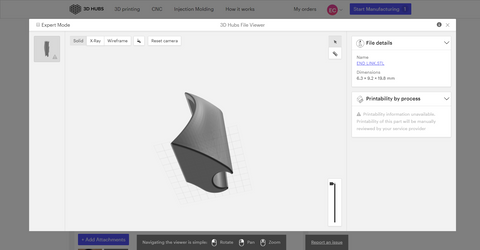

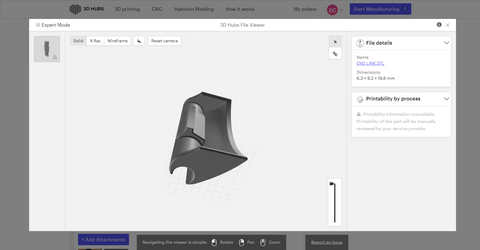

Then we translated that into a CAD, and then into a technical file for 3D printing. After some back and forth with our CAD guy, we refined the shape, dimensions and loaded it up for printing.

I printed it in PLA (corn plastic) first and was shocked to find it was a perfect fit on the first go! Pretty rare, as those of you who 3D likely know, or maybe I just need to upgrade print skills.

With the plastic prototypes in good shape, I went ahead and printed them in titanium. Those also turned out a spot on fit. The only thing with the titanium prints is that the laser sintering leaves a kind grainy finish on the surface. Not the worst, but also not matching the COURG finish.

So, once the print is complete, we also need to hand grind the surface closer to smooth to remove the texture. After that, we still have to sandblast each endlink to get the matte finish to match COURG.

What’s included?

- Exclusive custom 3D printed titanium grade 5 endlinks (2)

- Titanium flex band (1)

- Prototype maker backer mojo

Will they fall apart?!

Absolutely not. I’ve rocked this band for many months now, in the oceans, hiking, rock climbing, even rescuing babies (diaper changes can get downright treacherous :)).

Lead time?

Once we have orders in, I'll order the flex bands from Germany. At the same time, I already have a 3D printer nearby who is setup and ready to initiate fabrication of the end links. I estimate we'll have the first batch done in a few weeks.

Upside. (Likes)

- Completes the COURG titanium kit.

- The end links are 3D printed right here in the U.S.

- We'll make these out of titanium grade 5. (And yes, it will still match the grade 2)

- No extraneous hardware here to dig into my wrist or mess with the clean lines.

- Matte finish is solid and matches COURG.

- Very comfortable and does not add unnecessary weight or bulk.

- Customized personal fit. (at a small cost, see below RE adjustment)

- The links are solid titanium plates (NOT plated) or sandblasted steel or “titanium color”

Downers. (Notes for future upgrade)

- EACH link costs $60.00 to 3D print (2x = $120.00 to fabricate + hand finishing + the titanium flex band). Doesn't take a math wiz to see how there's not much (any?!) profit in this to keep it reasonably priced/accessible for everyone.

- I'm importing the bands from Germany, but at least they're well machined and precision.

- Once in a while, the band sometimes pulls when the watch gets caught on something.

- Hairy armed guys have mentioned being worried about snagged hairs between the links.

- Takes a little skill (and small screwdriver/needle nose pliers) to adjust these bands because there’s no clasp or tail to speak of. They come in a standard length and links need to be removed to get it just right. That, or any watchmaker can adjust for you in a few minutes.

- The hardware of the flex mechanism isn’t fully titanium, but it doesn’t feel heavy. And you can see the mechanism from the side view, which adds a nice mechanical and industrial feel, and I kind of like seeing the titanium U-clips.